President Bola Ahmed Tinubu was the political mentor of Grammy-nominated afrobeat musician Seun Kuti.

In a recent interview with media personality Chude Jideonwo, the late Fela Kuti’s son said this when discussing his connection with the president.

He emphasised that the president was a mentor to him as a child and that they have a “robust” relationship. He called the president “uncle.”

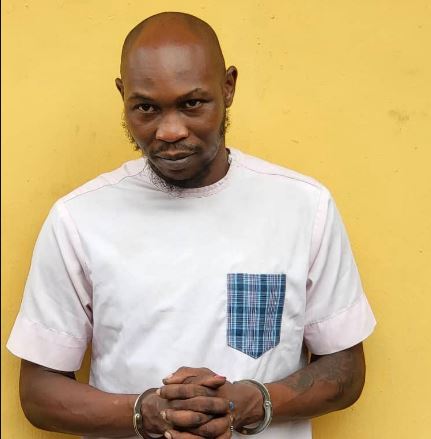

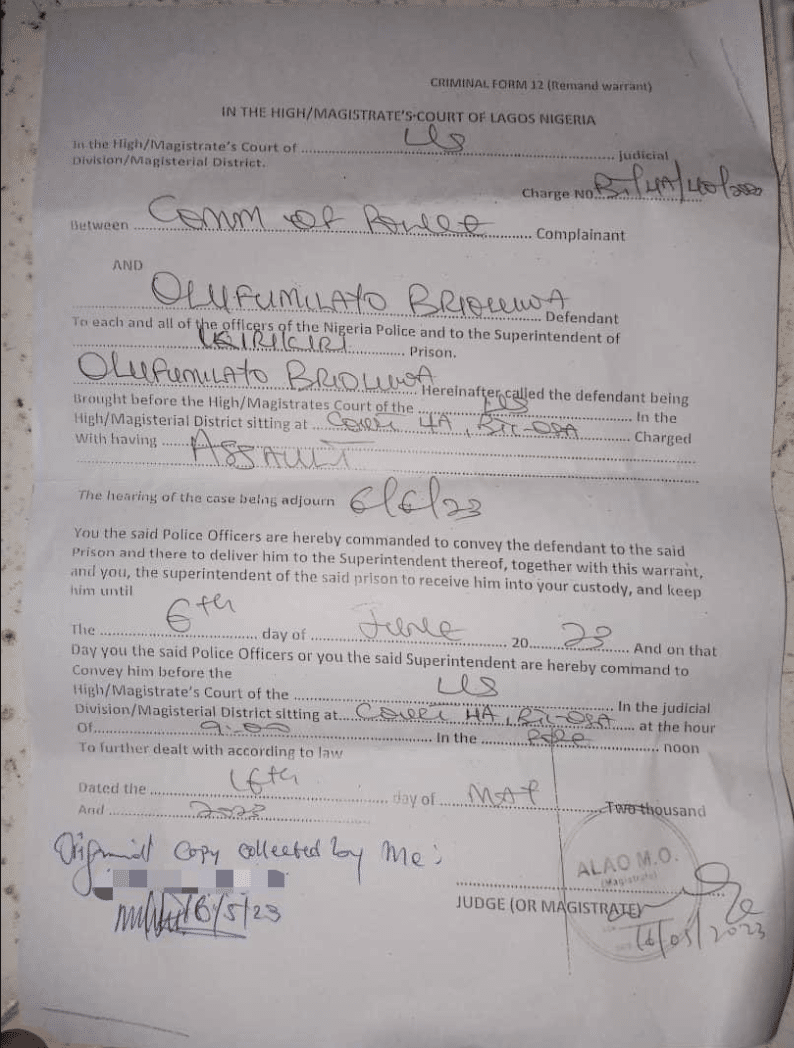

BREAKING: Seun Kuti Arrested After Assaulting Officer (Video)

He remembered that Tinubu was a key figure in the National Democratic Coalition (NADECO), which battled for democracy in Nigeria after the military threw out the Chief MKO Abiola-predicted June 12, 1993 presidential election.

Kuti said, “My relationship with President Tinubu on a personal level is very robust. I grew up knowing him as an uncle. He was a very good friend of uncle Beko [Kuti]. He was a political mentor to me growing up as a child.

“Many of the ideas that I understand today, it was these men that taught me as a child growing up. Knowing them fighting for democracy in this country with NADECO, even when he [Tinubu] went on exile… Wale Soyinka, uncle Beko, Asiwaju, these were the men who fought for our democracy.

“During Tinubu’s first term as Governor of Lagos State, I performed at all his rallies. I’ve always been close to him personally. But I don’t have any political relationship with him. And even at that, I don’t think it’s anybody’s business. I’ve not been to his house in years except when I need to see him for national issues.

Assault: Seun Kuti Apologized, Handed Police Officer 12,000 To Fix Car

“So, these things that people say are just to tarnish your image. They make it seem like everybody must be paid for what they’re saying. No, no, no. What’s the truth is the truth. And I say it regardless of fear or favour of anybody.”

He, however, said so far, President Tinubu has not been performing well.

Follow us on Facebook